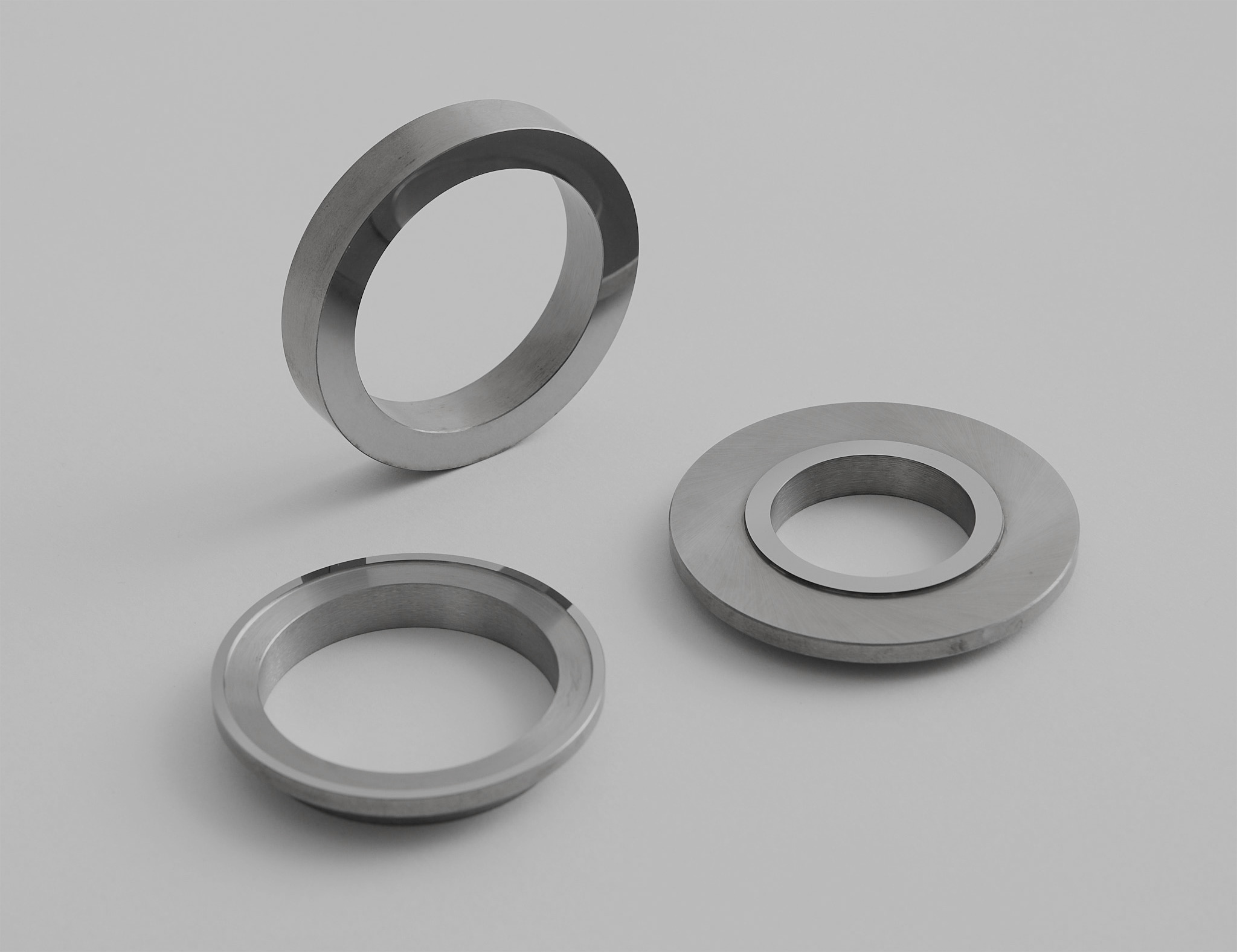

We operate several lapping machines, which enable us to offer a variety of surface finishes on parts of different sizes and materials, such as silicon carbide, tungsten carbide, ceramics, various steels, cast iron, etc.

Flat lapping is an essential operation for ensuring the optimal sealing of mechanical parts. This process involves machining the surface of a part to achieve specific flatness and surface roughness, thereby enhancing its contact with other components. The proper selection of abrasives and precise adjustment of our lapping machine parameters are crucial to meeting the required specifications. Typically, the lapping process is carried out in several stages: An initial material removal phase ensures the flatness of the part. One or more polishing stages are then performed to achieve the desired precision and surface finish. The quality of the lapping process is verified using high-precision measuring instruments, ensuring that the surface is perfectly flat and free of defects.