Description

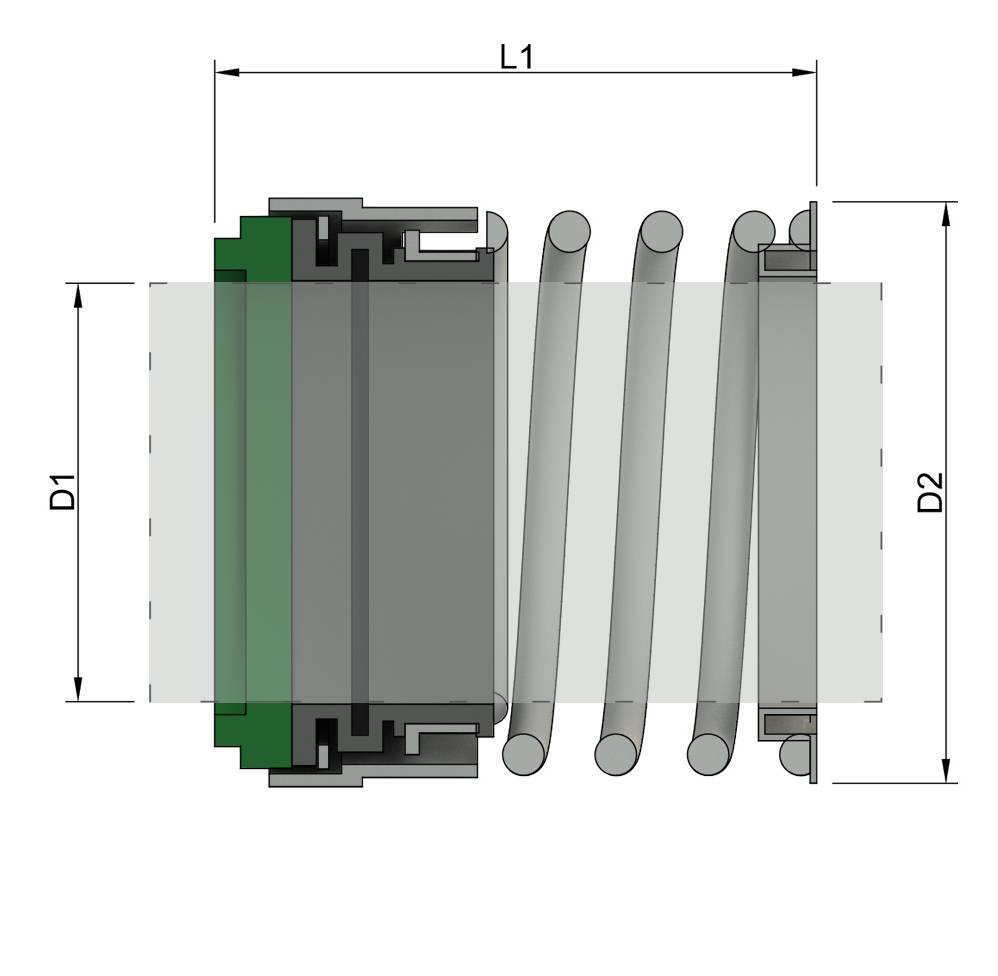

| Shaft | D1 | D2 | L1 |

|---|---|---|---|

| 1″ | 1,000 | 1,500 | 1,562 |

| 1-1/8″ | 1,125 | 1,625 | 1,625 |

| 1-1/4″ | 1,250 | 1,812 | 1,625 |

| 1-3/8″ | 1,375 | 1,875 | 1,687 |

| 1-1/2″ | 1,500 | 2,000 | 1,687 |

| 1-5/8″ | 1,625 | 2,250 | 2,000 |

| 1-3/4″ | 1,750 | 2,375 | 2,000 |

| 1-7/8″ | 1,875 | 2,500 | 2,125 |

| 2″ | 2,000 | 2,625 | 2,125 |

| 2-1/8″ | 2,125 | 2,812 | 2,375 |

| 2-1/4″ | 2,250 | 2,937 | 2,375 |

| 2-3/8″ | 2,375 | 3,062 | 2,500 |

| 2-1/2″ | 2,500 | 3,187 | 2,500 |

| 2-5/8″ | 2,625 | 3,375 | 2,750 |

| 2-3/4″ | 2,750 | 3,500 | 2,750 |

| 2-7/8″ | 2,875 | 3,625 | 2,875 |

| 3″ | 3,000 | 3,750 | 2,875 |

| 3-1/8″ | 3,125 | 4,000 | 3,125 |

| 3-1/4″ | 3,250 | 4,125 | 3,125 |

| 3-3/8″ | 3,375 | 4,250 | 3,125 |

| 3-1/2″ | 3,500 | 4,375 | 3,125 |

| 3-5/8″ | 3,625 | 4,500 | 3,250 |

| 3-3/4″ | 3,750 | 4,625 | 3,250 |

| 3-7/8″ | 3,875 | 4,750 | 3,375 |

| 4″ | 4,000 | 4,875 | 3,375 |

Other material combinations, dimensions, and seat types are available upon request.

A mechanical seal, also known as a sealing gland, is an essential device used in pumps, compressors, agitators, mixers, and other rotating equipment to seal the rotating shaft and prevent fluid leakage. It is composed of several elements, including friction faces, sealing rings, springs, and support components, designed to withstand wear and varying operating conditions. The mechanical seal ensures the reliability and efficiency of equipment by maintaining a seal between the rotating shaft and the fixed housing of the equipment.